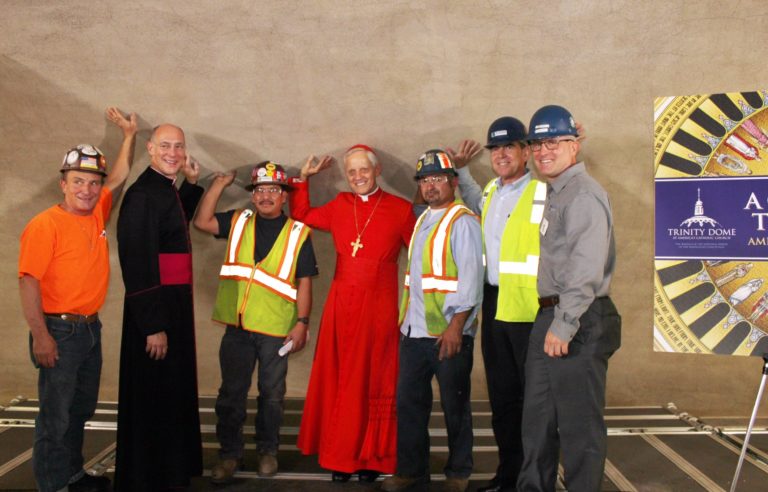

It is not often that a Cardinal blesses workers, scaffolding and equipment with Holy Water, but that is what happened at this job site. The National Shrine of the Immaculate Conception in Washington, D.C. is the largest Catholic church in North America, and one of the ten largest churches in the world. It is a prominent Roman Rite Catholic basilica and is designated both as the national and patronal Catholic Church of the United States.

The Trinity Dome mosaic project is the final phase of the construction being completed in this church that began more than 100 years ago. This is one of the largest mosaic tile installations in the world, consisting of 14 million pieces (24 tons) of Venetian glass tiles that will be affixed to the dome.

Moving workers and materials up to the elevated work platform and onto the scaffolding up in the dome presented a significant challenge. This was accomplished with the combination of stair towers, a transport platform, the Beta Max MC2000PMB personnel hoist and 2 Beta Max high speed wire rope hoists. One of the Beta Max Gemini high speed hoists was set up to service a material loading area outside where it was used to hoist materials being unloaded from trucks on the ground level up to a platform area on the side of the basilica. Another Beta Max Gemini hoist was rigged up in the very top of the inside dome to service the multiple decks of scaffolding.

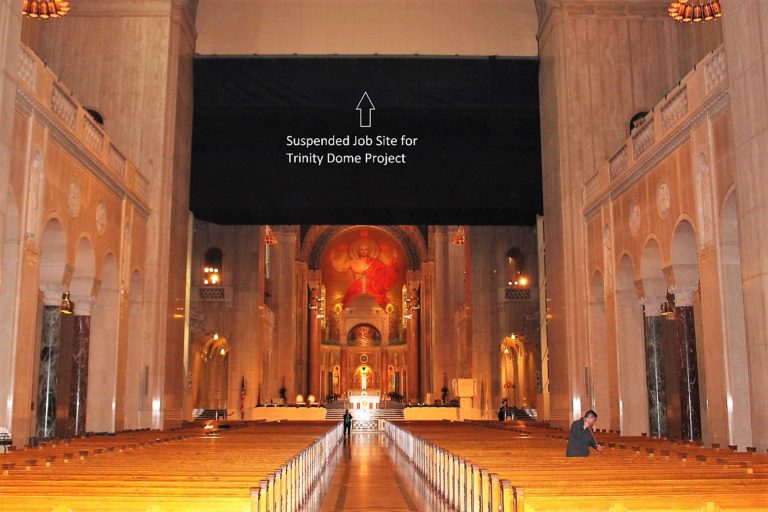

One aspect of this project that makes it so unique (other than the basilica itself) is the fact that this massive project is all taking place as high as 16 floors above the pews of the basilica. The entire jobsite, including the scaffolding and a Beta Max personnel hoist, is suspended above the nave and completely sealed off from the rest of the basilica so as to not interfere with normal day-to-day services and operations of the fully open and functioning church. The amount of scaffolding, men and material involved (including air filtration, dust collection and air conditioning to control humidity for the tile work) that is all suspended above the pews in the church is truly mind-boggling.

When standing on the ground floor in the basilica, one would never guess that an entire job site is in place up above…there is just a subtle, black draped area overhead. The creed of “cleanliness is next to Godliness” comes to mind when looking around at the polished, beautiful interior of the church, which is a true testament to the care that has been taken to contain the dust and debris from the work going on overhead

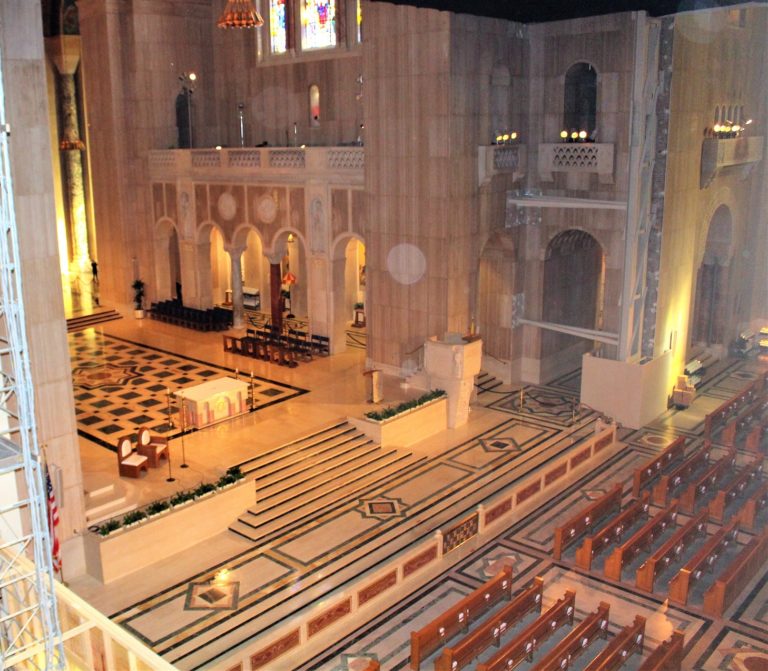

One particularly unique aspect of the Trinity Dome project was the installation of a personnel hoist (construction elevator) to move workers and materials up and down from the base of the elevated platform to the upper decks of the scaffolding in the dome. Scaffolding Solutions was the access supplier and they turned to Beta Max and incorporated a Beta Max MC2000PMB into their plans. The MC2000PMB is a small-footprint, lightweight personnel hoist with a 7 passenger / 2000 lb. capacity. This hoist was ideal for this project due to its ability to fit in confined spaces, lightweight characteristics, and relatively easy installation with less pullout and shear forces than larger hoists.

lb. capacity. This hoist was ideal for this project due to its ability to fit in confined spaces, lightweight characteristics, and relatively easy installation with less pullout and shear forces than larger hoists. Keep in mind, the scaffolding was not built from the floor, it is all “floating” on the elevated deck in the large domed space above the nave of the church. In addition, the hoist had to be integrated within a complex scaffolding structure that was designed and built with all access decks to within 8 inches of a 90-foot diameter dome 160 feet above the church nave floor. This was quite an engineering accomplishment considering that scaffolding is typically built in square and rectangle cubes.

The Beta Max MC2000PMB has sustained the project by carrying workers, mosaic tile materials, church clergy, and community dignitaries, as well as local press and broadcasters.

The Beta Max high speed portable hoists and the MC2000PMB personnel hoist provided a constant flow of workers and materials up and down on this complex project to significantly reduced delays and enabled the contractors and work crews to increase productivity.

When Beta Max was originally contacted by Scaffolding Solutions, it was immediately clear that this project would involve extensive collaboration and coordination between parties. Steve Singleton, sales team member at Beta Max was involved in the early part of the communication. “I could tell as soon as they (Scaffolding Solutions) started describing the project to me that I would need to get our tech department involved to see if this was even going to be possible, because the hoist needed to be disassembled into 3 sections, lifted to the platform and then reassembled in place up in the dome.”

disassembled into 3 sections, lifted to the platform and then reassembled in place up in the dome.”

Shanon Beekman, who is the department head at Beta Max for Tech Support, Product Design and Training said, “This was definitely one of the most unique projects I have worked on. It took a lot of back and forth dialogue and time spent going over drawings to make sure the hoist was going to fit, had adequate support, and that the tie-ins to the steel spine would work. This sort of project is time consuming, but the challenging aspects are also what make it rewarding when it is all said and done. This took a lot of people working together and I am proud of what we were able to accomplish.”

The result of this effort will be the creation of a lasting structure with great artistic beauty and purpose for generations to come. If visiting the D.C. area, this is definitely a place worth putting on your agenda to visit. Located at 400 Michigan Ave NE, the National Shrine of the Immaculate Conception is awe-inspiring, and contains an unbelievable amount of stunning artwork, mosaics and Italian marble.

To say that this particular project is unique is obviously an understatement. However, the same hoisting solutions being utilized on the Trinity Dome project can save time, increase safety and increase productivity and profits on any multi-story job site. Go to www.betamaxhoist.com or call 800.233.5112 today to find out which hoists would be applicable to your next project.

By Troy Palmer