Testimonial: BETA MAX MC1600 Transport Platform at the West Point Museum

The BETA MAX MC1600 was key to the West Point Museum restoration, allowing safe, efficient material transport while meeting strict structural guidelines.

Complete roof replacement at the SkyPoint Condominiums, a luxury 32-story building in the heart of downtown Tampa, FL.

How to remove all the debris from the rooftop of a 32-story building with the following conditions:

Quality Roofing Inc. provided a very smart, discreet, efficient, and cost-effective solution: a combination of BETA MAX’S LEO VFD and GEMINI PLUS High-Speed Portable Hoists mounted on scaffold bays erected on the rooftop and the 8th floor deck.

Quality Roofing came up with a similar solution using BETA MAX Hoists on a previous high-rise project in Tampa. It worked well, so they decided to propose this setup to the customer. This turned out to be a large part of why they were awarded the project, because it allowed for minimal contractor traffic through the interior of the building, the least possible inconvenience for the residents, the smallest mess, and an overall inconspicuous project that would meet the demanding timeline.

A local scaffold company (CAE, Inc.) was contracted to design and build engineered scaffold bays to support the hoists.

The LEO VFD Hoist was installed on an I-beam, with the I-beam Trolley Top on the rooftop at the 32nd floor.

Debris was bagged in dumpster bags and attached to the hoist. Once one worker had the bag filled and secured to the hoist, another worker used a tag line attached to the hoist to slide it out on the beam which was cantilevered over the parapet wall.

Load was then lowered straight down onto a wheeled dolly waiting on the 8th floor deck.

At this level, one worker was operating the hoist and guiding the loads onto the dollies, and due to the glass façade, another worker tended a tag line attached to the dumpster bag to keep the load from swinging into the building in the event of a wind gust etc.

Note: It is important that the loads are lifted and lowered vertically, straight up and down, not at an angle or incline. The tag line in this case was to prevent the load from swinging as it traveled the height of 24 stories.

Once the load reached the dolly, it was wheeled across the deck to another scaffold bay equipped with a GEMINI Hoist, also mounted on a cantilevered I-beam.

The load was then lifted off the dollies and over the parapet wall, and lowered to the ground level sidewalk where the rollaway dumpsters were located.

With the success they have had during the debris removal process, they now intend to use the same setup and hoists to lift all the roofing materials once the current phase is complete.

Contact us to find out how our hoists can help you work more efficiently. The number of applications and situations where you can increase safety and lower costs with BETA MAX Hoists will surprise you.

With the success they have had during the debris removal process, they now intend to use the same setup and hoists to lift all the roofing materials once the current phase is complete.

Contact us to find out how our hoists can help you work more efficiently. The number of applications and situations where you can increase safety and lower costs with BETA MAX Hoists will surprise you.

Stay up-to-date with the latest news at BETA MAX Hoists!

We use Mailchimp as our marketing platform. By clicking above to subscribe, you acknowledge that your information will be transferred to Mailchimp for processing. Learn more about Mailchimp’s privacy practices and Beta Max Inc.’s Privacy Policy.

You can unsubscribe at any time by clicking the link in the footer of our emails.

The BETA MAX MC1600 was key to the West Point Museum restoration, allowing safe, efficient material transport while meeting strict structural guidelines.

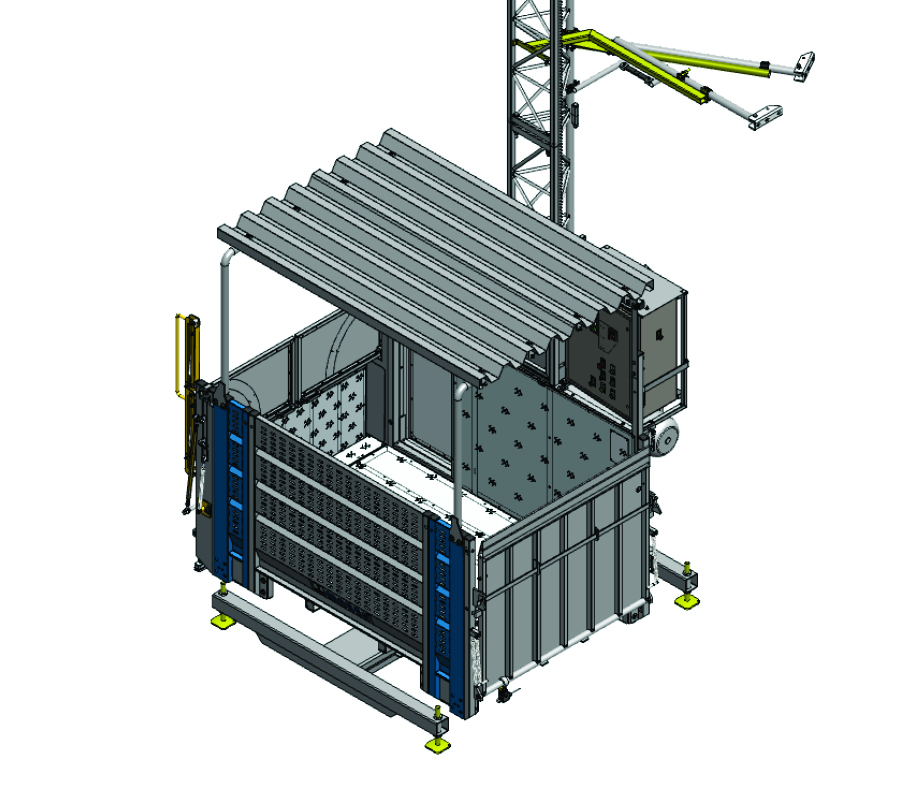

Get a Quote for the new MAX CLIMBER 2500TP/M MV >>> INTRODUCING THE NEW MAX CLIMBER 2500TP/M MV A Cost-Effective and Versatile Transport Platform/Material Hoist BETA MAX’s new MAX CLIMBER 2500TP/M MV is designed to deliver superior performance at a reduced cost, offering exceptional versatility and reliability on job sites.

Scaffold Resource utilized a Maxial Track Hoist and a MC2000PMB Personnel Hoist in their recent restoration work on the Cape Hatteras Lighthouse.

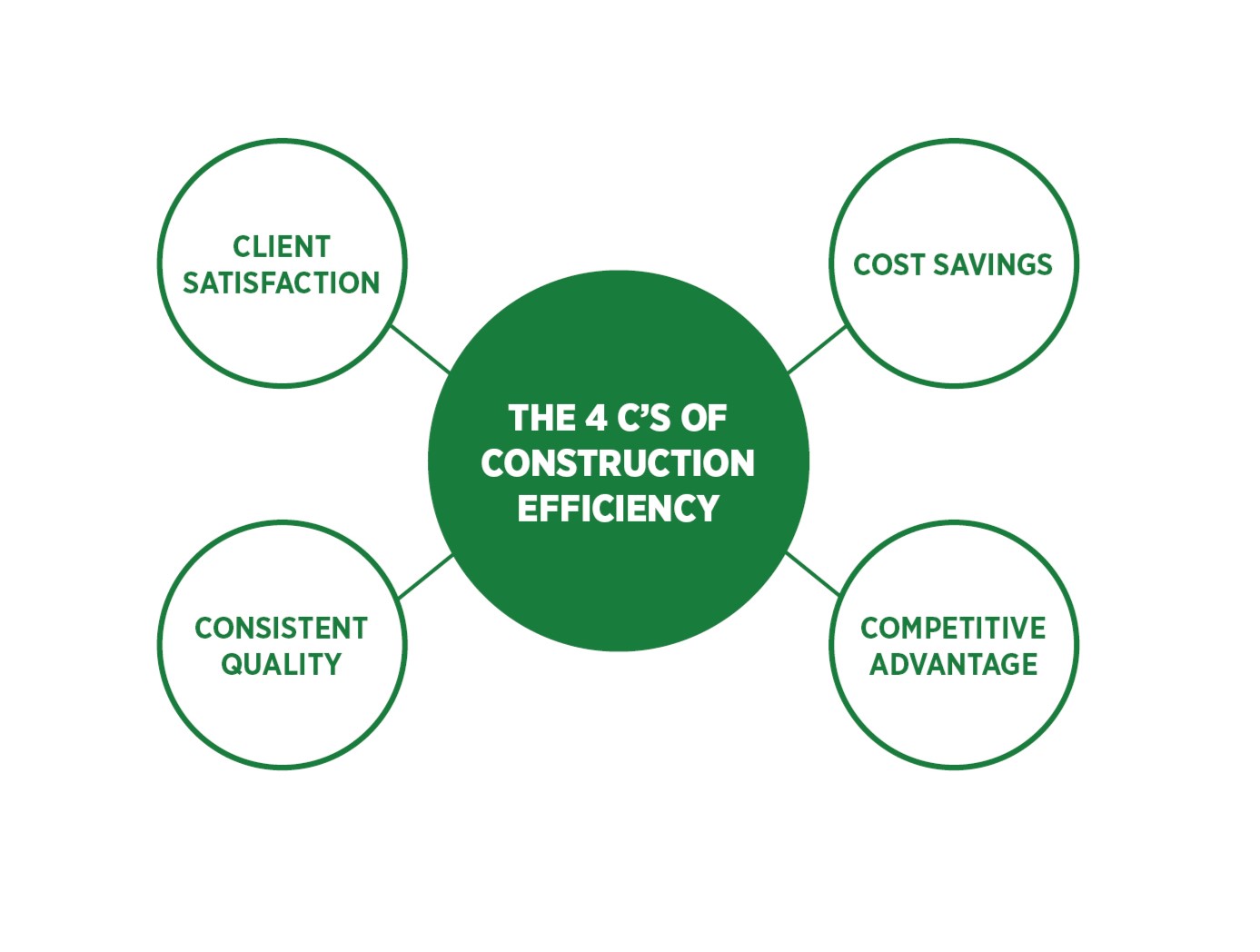

Efficiency in construction is crucial for completing projects on time, within budget, and with high quality. Key benefits include client satisfaction, cost savings, consistent quality, and a competitive advantage. BETA MAX Hoists enhance efficiency by accelerating material transport, reducing labor costs, improving safety, and offering versatile lifting options. These hoists streamline construction processes, leading to more efficient, safe, and cost-effective projects.